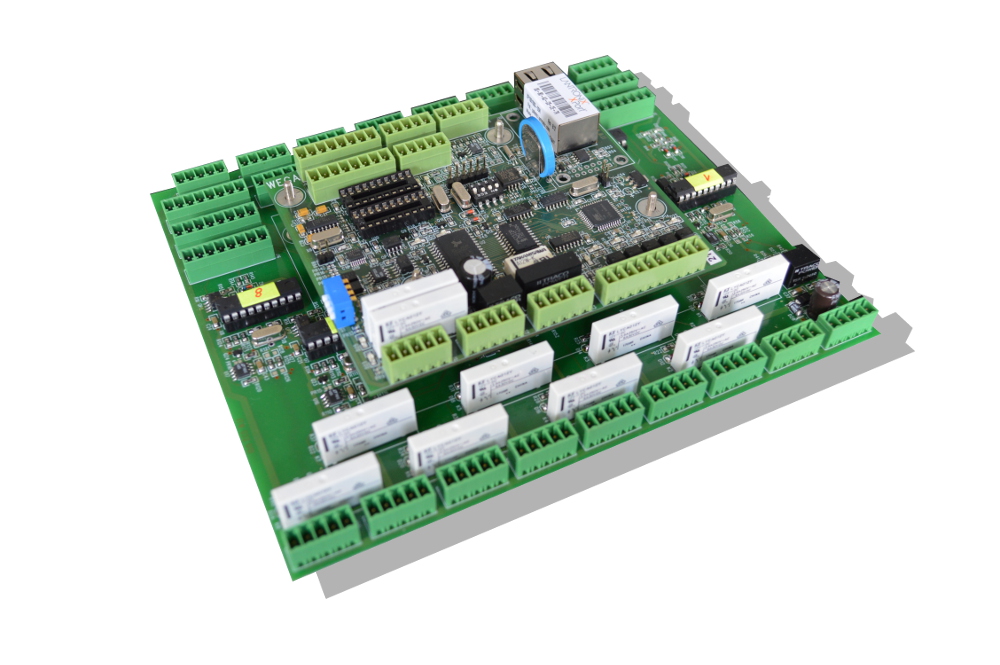

This control unit is used for connection into the WIS access system. Its construction makes it designated for installation into the lower ceiling with an ability to connect two reading units. For the dragON technology it supports connection of reader heads with the RS 485 interface. It is equipped with a controlling microprocessor x51 and it is able to connect up to 8 reader heads WEGA of the KRBox type or up to 8 APERIO HUBs. It also contains new diagnostic LED diodes which check the functions of the functional departments of the reading unit. When it comes to operation, it can work in an online mode, with the ability to switch offline in case communication problems appear.

|

Versions of the WE_CU-IP control unit |

|

||

| WIST02CU-IP | WE_CU-IP control unit |

Plastic cover |

|

| Technical parameters | |

| Dimensions | 190 mm x 140 mm x 70 mm |

| Weight | 400 g |

| Voltage/Power supply | 9-14V DC |

| Max. consumption | 150 mA pri 13V8 |

| Data memory | SRAM 128 kB backed up by internal battery |

| Galvanic separation | Only bus RS 485 |

| Communication interface | RS 485 |

| Number of all or nothing relays | For dragON technology needed to add product Input/Output module for the WE_CU dragON system |

| Max. switched current | 6 A DC, LED diagnostics of relay conduct |

| Inputs | On WEGA reader head - door opening sensor |

| Number of reading heads | 1 to 8 |

| Interface of connected reading heads | WIEGAND, RS 232 |

| Display | No |

| Range of working temperatures | -25, +50ºC |

| IP coverage | IP 56 - plastic cover |

Inputs/Outputs

The control unit contains predefined inputs and outputs. Their function is apparent from the connector description J4. The active state of the inputs is given by the configuration of the control unit, and configuration can only be done from the configuration utility. While using the outputs (relay contacts) and controlling the charge of an inductive character the contacts must be connected correctly to the control unit. The positive pole of the controlled charge always must be connected to the NO or NC contacts. While controlling the electromagnetic locks the safety diode must be connected in reverse direction. .

Certificates

Certificates

ID card printers

ID card printers  Appending labels

Appending labels

Customer support link

Customer support link